The Robey and The Robey Hall, RH Gallery at The Three Arts ClubHistoric

Part 2 of 3 - Strategies to help you through your historic renovation project

For many years the Burlington Room inside Union Station sat vacant with key features buried behind walls and acoustical ceilings. Amtrak saw the opportunity to bring back the past and re-create the space as it was 91 years ago, while giving it a new purpose and function. Undertaking the historical project meant adjusting the construction process to include additional measures.

In my first article, I shared how to get started when evaluating a historic renovation project. In this article I share some of the steps in the construction process that are unique to historic renovations – what's happening before construction workers arrive on site. Once you've made the decision to proceed and defined your vision, it's time to start exploring the design. The earlier you start to plan for the specifics, the better – but you'll need help from your team.

Early involvement of the right team members

For almost all historical renovation projects, we're part of the team at schematic design. In fact, the core team is a little bigger than on a new build because in addition to the architect, engineer and contractor, the project includes a historic consultant and historic tax credit attorney, who will help determine project design constraints. The consultants and construction manager are critical to the design process. They will help you negotiate what can be changed and to what level, offer cost-effective suggestions for alternative materials and methods that accomplish your design and put together an accurate budget based on relationships with key trades - all information that you need for your documentation upfront.

For example, on the RH project, the entire first floor, including paint, and portions of the second floor were land-marked so features had to remain in place, which presented constraints for the gallery design. We helped negotiate a compromise, which involved keeping portions of the corridor while opening other space to create the aesthetic and flow through the building that the owner and architect wanted.

Extra planning. Extra measures.

As with any precious artifact, historic architecture is treated delicately. It's important to understand the process and considerations that are unique to these types of projects.

Investigative demo for structural integrity

Often, there are no drawings that indicate the original structure so before design and construction it's important to start with an investigative process. At Pepper, we use our in-house certified quality team to conduct upfront analysis of the foundation, structure and building envelope – the systems that typically present the biggest unknowns. The design and contractor team, along with the consultants and key trades, will use the information to determine the constraints of the project.

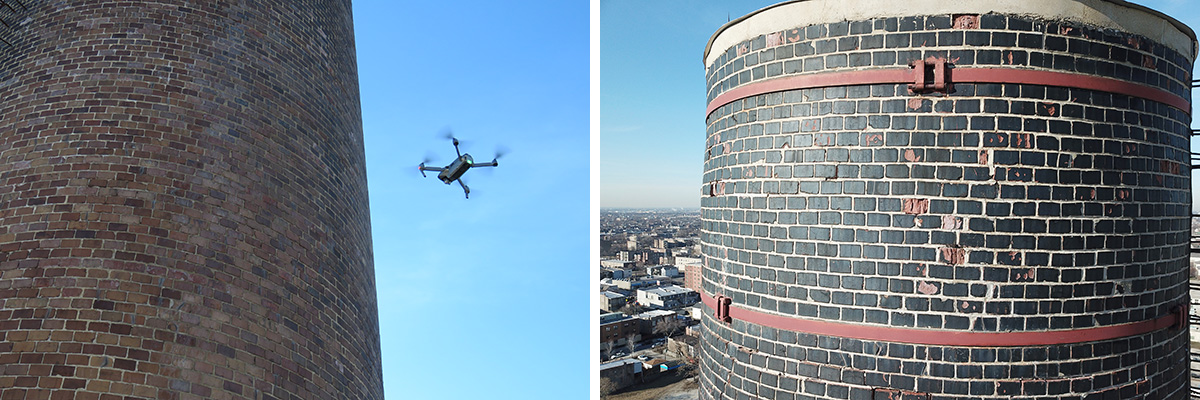

Façade inspections

The building façade is another area that we investigate thoroughly upfront. Today, Unmanned Aerial Vehicles (UAVs) – or drones – are used for façade surveys. They offer an inexpensive, safer and faster alternative for "seeing" and documenting the conditions of materials at higher elevations, like masonry facades. They can also be used for interior inspections. Heat loss image photography is a fast and accurate way of detecting air and vapor problems that may otherwise go undetected by hand.

Environmental investigation

Contaminated materials, like lead and asbestos, are common in older buildings. The level of contamination should be determined during the investigative process, and then time for abatement and addressing environmental issues should be incorporated into the schedule.

Surgical demolition

The investigation process continues into demolition, and all the information that has been gathered so far is used to establish the project budget. The demolition process is akin to surgical demolition, rather than mass demo. Since materials are often salvaged and reused, they are dismantled instead of discarded. And we constantly monitor vibration and change our methods to not exceed the established limits.

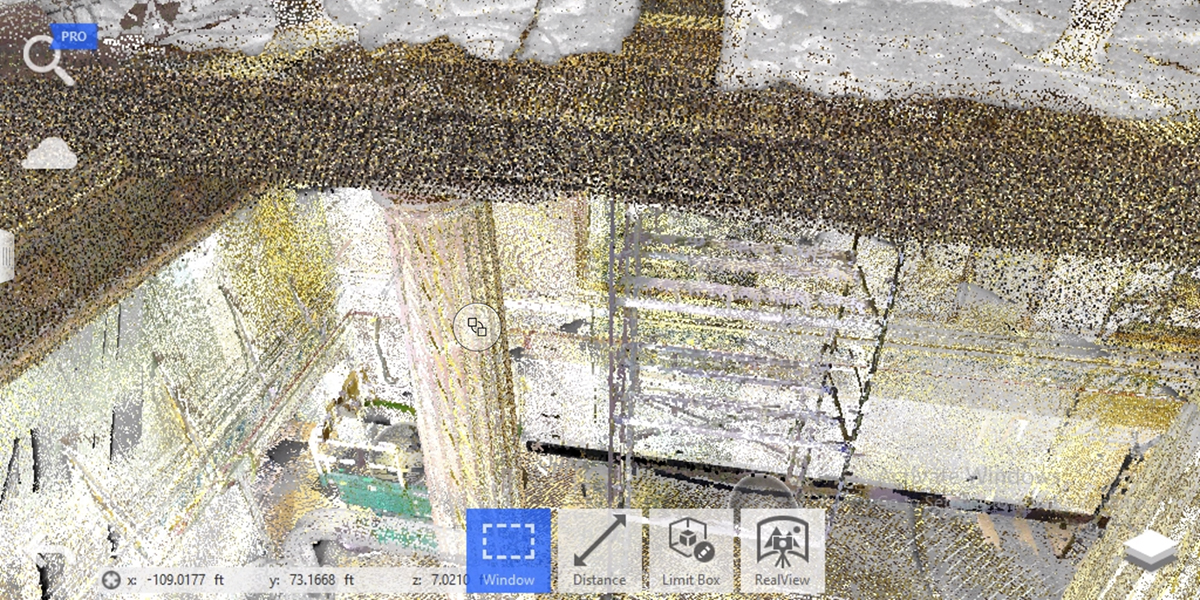

Today, laser scanners offer a faster and more accurate way of capturing existing conditions than field measurements. When done after rough demolition, the scans can be used as the basis for coordination. They can also be used to replicate unique features. For the Union Station Burlington Room, we scanned the area above the ceiling to coordinate mechanicals and lighting that would be located above the ceiling. This allowed the architect and trade contractors to know the exact conditions.

DOCUMENTATION

Once the demolition work begins, pieces that are designated landmarked items are catalogued where they came from so they can go back in the same place. So, for example, when we work on terra cotta facades, the material is fragile, and several pieces break in the process. We number the parts that are saved, recreate broken pieces and place them back in the order in which they were removed.

3RD PARTY APPROVALS

For historical landmarks, National Park Service and SHPO approvals are required during the project. Mockups of the design and material samples must be approved for any feature designated as historical, and new materials and features must match the original profiles and color. It's important to allow time in the schedule for these approvals – and extra time for multiple submissions.

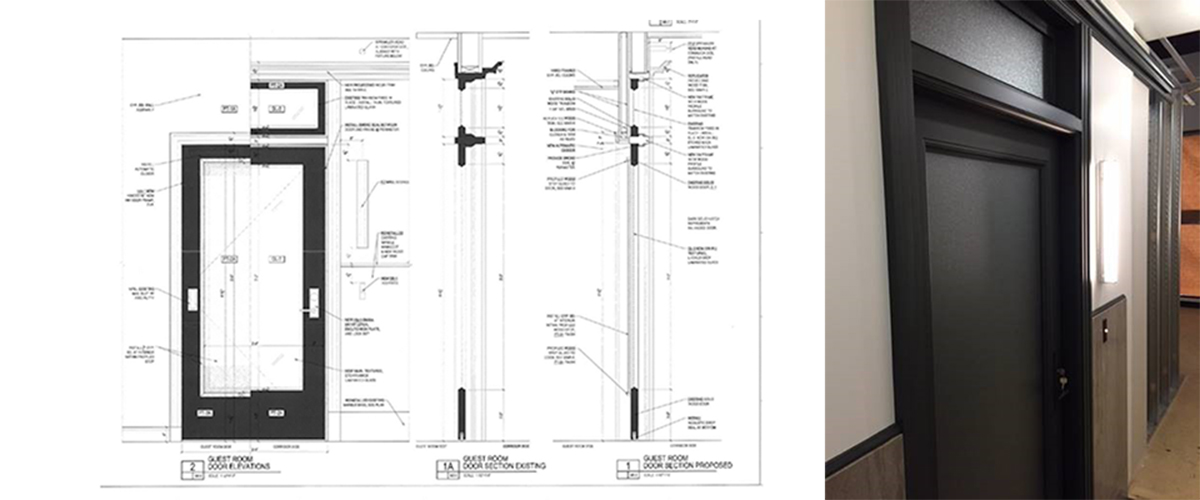

HAND CRAFTSMANSHIP

Once construction begins, the work itself often requires extra time. When restoring the original look and bringing it up to today's codes, we still match the original level of workmanship, which often requires a degree of hand craftsmanship.

For example, when we proceeded with interior wall demolition on each floor of The Robey, we were required to retain the wooden doors with glass lights. The doors were unique, and they were not fire-rated for a hotel. So, we removed each one and set it aside, repaired the wood, removed and re-attached new hardware that matched the original and added drywall to the back – before putting them back in place.

Worth the wait

Bottom line: the extra requirements with historic renovations can take more time. Fortunately, activities that used to be accomplished entirely by hand are now supplemented with technology to help facilitate the process and improve accuracy. Your team can help you find innovative solutions that minimize constraints and keep you on track with your investment. The extra efforts involved are well worth it.

In the third article, I'll discuss the workmanship that is involved in preserving some of the historical features and architecture while making them compliant with today's codes and occupancy needs.

About the Author