Virtual construction & technology, Industry insights

On an almost daily basis, I see my two sons interacting with some sort of digital technology. This may not seem like a profound statement, but my older son just turned three and my younger son is only 18 months old. They can both navigate a smart phone and tablet with ease. They know that the device has to be unlocked, where the kids’ apps are located and how to switch back and forth between their favorite apps. My oldest has even learned that regular YouTube is better than YouTube Kids.

I was lucky enough to take a typing class when I was in 5th grade, which prepared me very well for the computer’s influence within our business world. Today’s students are introduced to computers when they enter elementary school, and by the time my children are in school, typing may be obsolete due to mobile touch screens and voice-activation commands.

While new tools and applications offer many advantages, to those unfamiliar with how they work or their benefits, they can also present challenges and frustrations. Fortunately for our teams, the materials and means of constructing buildings has remained relatively unchanged over time.

We are still installing concrete foundations, using steel columns, and building walls with 2x4s and sheetrock. What has changed within the industry are the tools and techniques, thanks to the use of technology in its many forms. From the ever-changing nature of "blueprints" to drones and 3D printing, new technologies are being applied to construction all the time.

My role at Pepper is to keep a close eye on these emerging technologies and evaluate them based on how they can improve our productivity, our product and our services.

Technology's influence on how we run our business

When my great grandfather started Pepper Construction with a crew of carpenters in the Merchandise Mart, he made a commitment to be the best contractor he could be for his clients. As we have sought to maintain that commitment to our clients over the past 90 years, we have found that being the best looks much different today than it did even 10 or 20 years ago. Today, our systems and software programs are more important to the product and services that we provide and the type of company that we run.

End-to-end vs. niche platforms

Within the industry, there are a few major software players that offer end-to-end solutions, from project estimating and costing, to financial consolidation of the company’s general ledger. While broad in their capabilities, often they lack the ability to be highly customized to a specific business or project need.

When customization is needed, companies turn to niche software. These smaller products have a heavy focus on the mobile portion of their software. They aren’t interested in being a one-stop shop, and because of this, they include the ability to integrate their product with a multitude of other products, resulting in a patchwork of task-specific software.

As each races to be the preferred industry solution, both platforms continue to sharpen their offerings, and in turn, improve the level of service in our industry. Software and technology questions are becoming very important to our company, our partners and our clients.

Technology's influence on how we run our projects

Just as the software landscape for running a construction company is changing, technology has brought an evolution to the drawing creation process that has affected us at the project level. It wasn't too long ago that the only way to produce drawings was in 2D, blueprint form.

Changing how we create the plans

According to Evolution of Computer-Aided Design, published in Digital Engineering: In 1957, the concept of electronic drawings came to fruition, but it was not until the release of the IBM PC in 1981, the subsequent founding of Autodesk in 1982 and release of AutoCAD in 1983 that the wide scale use of the technology became feasible. AutoCAD helped to improve the efficiency and accuracy of drawings, but ultimately, the drawings themselves were printed out and mailed to contractors for bidding and construction.

Changing how we access the plans

With the introduction of the iPad in 2010, the tablet computer was invented. Since that time, it has become increasingly important to provide access to electronic drawings via these devices. Our superintendents and field personnel can now easily see the most recent version of a drawing on their tablet and be confident that they are constructing the building as intended by the architect and owner.

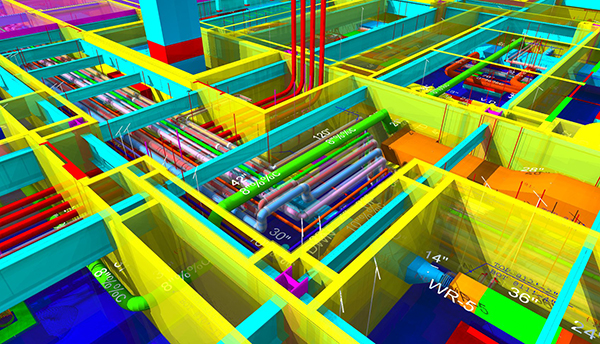

Amid these changes to the drawing creation process and the means of accessing drawings, Autodesk revolutionized the industry by purchasing the creator of the building information modeling (BIM) software Revit in 2002 and is still continuing to evolve Revit through today. Revit and other similar modeling softwares have allowed us to create intricate 3D models that show complex representations of a building’s structure, its MEP systems and other architectural details, while also including the specifications and data for each component.

Changing how we visualize the plans

Beyond tablets, we are exploring how we can experience the spaces that we are modeling with virtual reality (VR) and augmented reality (AR) hardware and software. Just this year virtual and augmented reality were available to mass consumers via countless devices, at a very low cost of entry.

Most of these devices are simply a headset attachment for your smartphone. Though still in its infancy, some of the commercial VR and AR products that will better meet the needs of construction are the Oculus Rift, the Samsung Gear VR, the HTC Vive and the Microsoft Hololens. For an industry not known for technology, we stand at the forefront of adoption and are leading the discussion about how this new technology can be applied. Next month, we will share more information about the different applications of the various platforms and devices.

I like to imagine a future along the lines of this video by Trimble, for how AR will impact the construction industry.

Changing how we work from the plans

No one knows exactly where the industry will go. VR and AR technologies are just one type of technology among many that are already here, including UAVs (drones), 3D laser scanning/reality capture and 3D printing.

I believe that in the next five to 10 years, we will not be looking at drawings on paper, a computer, or a tablet, but rather, we will be wearing devices like the Hololens, which will show us exactly what we should be building, represented at scale, within the space or area that we are working.

Technology's influence on how we staff our work

With all the changes in technology that we have seen and a potential for much larger change in the near future, we have to think very critically about how our employees will accept and embrace these changes. Already, our various departments have had to undergo significant amounts of training to keep up with new equipment and processes.

Today, we have departments and employees with skill sets that didn’t exist ten, or even five years ago (virtual design and construction staff and training on BIM-related software). In the survey we conducted last fall, we heard our subcontractors tell us they are also considering different skill sets when hiring. This trend is here to stay.

More to come

As a company headquartered in Chicago, one of the largest US markets, we compete with some of the largest and best contractors in the business. We are all investing in technology resources to remain competitive and lead our industry. The benefit of being a larger company is the ability to leverage the knowledge and skill sets from across our region to provide increasingly unique services and solutions to all of our clients throughout the Midwest and across the country.

Despite all of the benefits, smaller contractors have been slow to adopt new technologies due to low margins and cost barriers. Because of the low margins, we struggle as an industry with figuring out how to make these newer roles job chargeable, rather than another increase to our overhead. Perhaps an even bigger challenge than the cost is training current employees and hiring, developing and retaining teams with the skill sets needed to take full advantage of the technology. The companies that adopt the right technologies and figure out how to integrate them into their operations the fastest will be the winners.

How has technology changed construction? It has gone from a supporting function to a business driver. Construction has come a long way because of technology, particularly over the past 30 years. Yet, we are still gaining momentum, and we are still an industry ripe for innovation.

This is the first in a series of posts about the changing image of construction. We will be discussing current challenges and opportunities associated with the business of construction and the impact on our projects.

About the Author