-

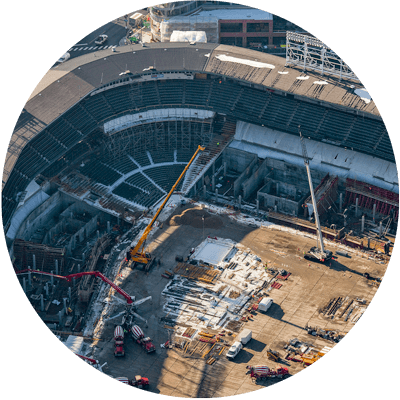

Bringing History into the Future

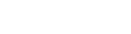

Complex engineering techniques restore and enhance Wrigley Field to ensure it stands for generations to come.

- Project The 1060 Project

- Location Chicago, Illinois

- Owner Ricketts Family

- Owner's Representative CAA ICON

- Architects Populous, Stantec

- Lead Engineers Thornton Tomasetti (SE), ME Engineers (ME), ESD (ME), and Terra Engineering (CE)

- Photography Ballogg Photography, Bob Elmore Photography

Six years after construction began on our most high-profile project ever, we join our partners in celebrating the long-awaited restoration and expansion of Wrigley Field. The journey began in 2010 when we received a phone call to explore ideas that would improve the second-oldest MLB ballpark, not knowing it would turn into the project of a lifetime.

The 1060 Project captured the interest of everyone familiar with Wrigley Field. Our renovations touched every area of the park, from the bowl, concourses, concessions and bleachers to player facilities and adjacent open-air community space. We revived the historic façade, signage and even the historic caretaker’s house.

Modernizing the more than a century-old ballpark while preserving its history was an engineering feat like no other. The structure was essentially lifted onto stilts in order to replace the foundation and build new supports for the expansions above.

Earth Retention

Virtually every possible earth retention system was used to protect the ballpark and surrounding streets during excavation. This was necessary so as not to compromise the integrity of the existing structures in the process of making them more sustainable.

The unseen work proved to be the most demanding. Replacing infrastructure, shoring structures and streets, excavating down 30 feet while only inches away from existing facilities, as well as adding subterranean structures and even a tunnel, were just a few of the challenges.

Secant Pile Walls

Due to the elevation of the ballpark foundations and their proximity to the new basement, a top-down construction technique was implemented along with secant pile walls. These earth retention systems at the two-story basement areas mitigated the movement of the existing surrounding structures.

Cross-Lot Bracing

Cross-lot bracing was a cost-effective solution for the single-story basement of the office building and around the lower bowl, where the team was digging into the water table.

Grade Beam

A massive 400-foot long and 8-foot tall grade beam, sitting on more than 90 micropiles along the western edge of the ballpark, was installed to redistribute the expanded load of the upper level concourse and stabilize soil conditions between the ballpark and the adjacent open-air community space.

Sheet Piling

A steel sheet pile was driven 40 feet down into the silty clay where it met the hardpan to separate the excavated area from the ballpark and keep the surrounding soil from collapsing during construction.

Micropiles

More than 200 micropiles now provide the broad shoulders on which Wrigley Field sits. Each micropile can withstand 500,000 pounds of force, which in layman’s terms is strong enough to support the Statue of Liberty.

Tunnel

A combination of micropiles and injection jet grouting was used to allow the tunnel excavation to occur between existing column foundations.

Reflecting on all it took to restore and enhance Wrigley Field, we are proud of our work given the ballpark’s historic value and significance to our city. The enhancements blend right in, as if they always belonged there. Watching the players and the fans enjoy a better experience because of the work we did is like a home run – for us.