UNDERGROUND UTILITIES DAMAGE PREVENTION PROCESS

A New Safety Standard - In 3D

UIC – ACADEMIC & RESIDENTIAL COMPLEX, Chicago, Illinois

UNDERGROUND UTILITIES DAMAGE PREVENTION PROCESS

UIC – ACADEMIC & RESIDENTIAL COMPLEX, Chicago, Illinois

Liebman Science Center, McHenry County College

A stunning new science facility places the college’s values front and center.

Fittingly, the latest 3D-printing technology played a key role in Pepper’s latest project for McHenry County College: the Liebman Science Center. The facility will host classes for lectures and labs in biology, anatomy/physiology, chemistry, physics/engineering and earth science/meteorology. It features a minimalist design with large windows to maximize views of green space and allow natural light to flow in.

The new science center features:

The state-of-the-art facility caters to students pursuing careers in biology, physiology, chemistry, health care and astronomy. Classes in the facility began in late August with students and staff singing its praises.

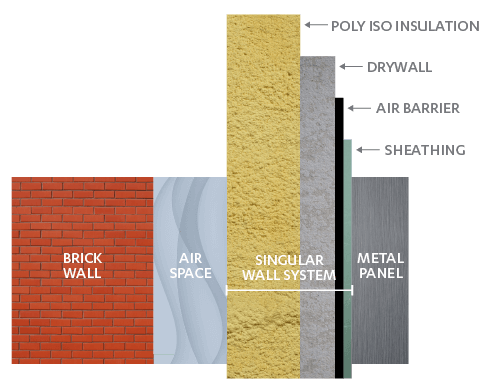

To keep costs down, the design called for a unique wall system that uses multilayered insulation panels instead of gypsum drywall. The system had to be installed precisely to keep the walls air- and water-tight.

If wall the system was not properly installed it would compromise the building in the future, leading to energy waste and the long-term degradation of the building’s masonry exterior. Here, you can see an example of what a compromised masonry exterior looks like.

During the install the connections were blind-fastened, which can be difficult. Joints were sealed with liquid flashing and special transition membranes were installed to improve compatibility. Each step in the complicated process was communicated clearly to all of the trades. The team used a 3D-printed model of each installation component — giving installers not only a 3D view on a screen, but also allowing them to see and touch the printed model. In turn, this enabled robust conversations with Quality Director Corey Zussman as we coordinated with subcontractors and architects on the building envelope details.

727 West Madison, Chicago, Illinois

Precision modeling on tight timeframes produced the concrete structure for this stunner in the West Loop.

Highland District Hospital Expansion, Hillsboro, Ohio

Laser scans of this century-old hospital produced data to build on.

Circle Centre Mall Renovation, Indianapolis, Indiana

Our augmented reality solution helped new art find its home in this stunning mall.

Underground Utilities Damage Prevention process

Collaboration and augmented reality technology help us reduce dangerous utility strikes.

© Copyright 2019 Pepper Construction - All rights reserved.