High performance & sustainability

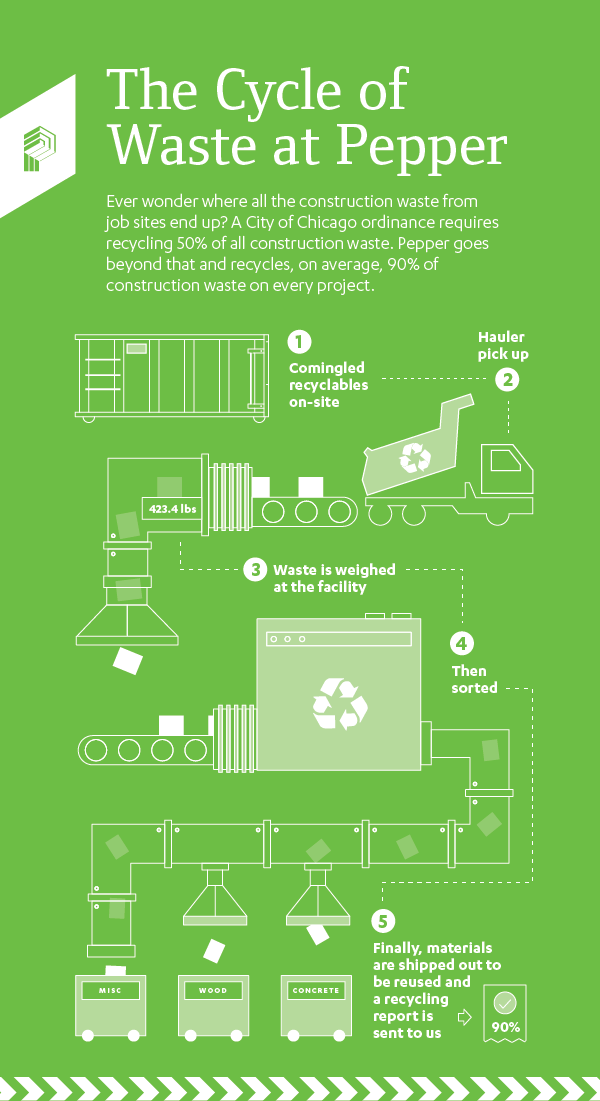

A City of Chicago ordinance requires recycling 50% of all construction and demolition waste. Pepper goes beyond that and recycles on average 90 percent of construction waste on every project. How do we set up our facilities to be able to achieve our goal of recycling 90 percent of all waste?

To begin the process, during the early stages of construction, we send material haulers a construction waste management plan. This plan contains information such as materials to be recycled, anticipated quantity, disposal method and handling procedure so that the haulers know what to expect when picking up the waste. Once demolition and construction have started, there are two different ways that the waste on site can be organized. Waste can either be separated on-site or comingled. When waste is separated on-site, each material from a different stream such as concrete, drywall and paper is separated into different bins to be sent to a recycling facility. If the waste is comingled, then all waste regardless of the material steam is disposed of into the same recycling bin to be sorted at a recycling facility off site.

Once the hauling company receives the waste management plan and the waste is collected at the site, the haulers come to transfer the materials to a variety of different recycling facilities. I recently had the chance to tour a local waste hauler to find out step by step what happens to the construction waste after it leaves our sites.

Upon arrival at the recycling facility, trucks weigh in, then all waste is separated into categories. A forklift picks up the waste to transport to a conveyor belt where the waste stream goes through automated sorting processes, after which workers sort the remaining streams by hand. Each worker is assigned a material type and takes that specific material off the conveyor belt as it goes by into a separate pile. Once those piles get to a substantial amount, they are then shipped out to a customer or to a third-party recycling facility where the material can either be broken down or repurposed.

Waste is distributed to a variety of interesting places after the recycling facility based on material and size. For example, concrete is often crushed and sent to manufacturers to be used in future concrete mixes. Wood can be repurposed as mulch and sold to residential customers or transformed into different sized pallets in demolition situations. We also partner with companies that participate in buyback programs as another option to recycle the waste from our sites. These programs are popular with carpet and acoustical ceiling tile materials.

Pepper believes that each project creates a unique opportunity for us to give back to the community. We strive to go above and beyond the local ordinance of recycling waste because of the significant impact that recycling has on the environment. According to the EPA, in the US alone, out of an estimated 892 million tons of consumer solid waste that is generated annually, two-thirds which come from construction projects. Recycling helps to reduce the amount of methane pollution caused by waste in landfills and reduces demand for raw resources. Recycling 90 percent of our construction waste is just one of the ways Pepper plays a role in making a positive impact on our environment and the people that live within it.

About the Author