Despite market uncertainty, construction activity is maintaining momentum. Multiple mega projects are launching as ongoing maintenance and renovation work forges ahead. Throughout the Midwest, concern about available skilled manpower is growing amid an already tight labor market.

Trying to accomplish more with less is never easy, especially when it comes to work in acute care facilities. Hospitals face manifold challenges and external pressures that require continuous investment in facilities — aging infrastructure, higher census and constrained spaces, prioritization of revenue-generating spaces, plus the ever-present need for the latest technology. These are compounded by the complexity of getting everything to fit, connect and integrate within existing operations, all without disrupting ongoing patient care.

Technology is a rising, reliable powerhouse in the healthcare sector, allowing us to solve problems, stretch dollars and create efficiency. The following five use cases demonstrate the competitive edge gained by leveraging technology to achieve project goals, even in the most demanding situations.

01. Build it virtually first

Creating a simulated user environment on the Emergency Department renovation at Advocate Christ Medical Center was key to addressing the medical team’s emphasis on the importance of standardization when entering and exiting the new exam rooms. The renovation included variations in room size, existing column layout and location of MEP risers. Using building information modeling (BIM) and virtual reality (VR), the team explored a standard room layout within those variations.

When modeling the room, we aimed to ensure consistency for operational efficiency, find opportunities for replication and prefabrication, and eliminate unforeseen changes in the rough-in plans. The architect revised the designs and applied these ideas across multiple room types before any rough-in occurred. This prevented costly changes in the field during construction.

The owner also identified changes through their review of the virtual mockup, including the following:

- Placing outlets in the same locations

- Adjusting the rough-in location of exam lights to avoid conflict with the adjacent room lights

- Turning the IV track to avoid interference with the patient

- Removing an unnecessary cabinet

- Adjusting light switches so all switches and hand sanitizer fixtures are located in the same place

- Adjusting the location of movable cabinets to avoid low HVAC returns

02. Capture existing conditions quickly

Laser scanning is a form of reality capture that is used to quickly and accurately (within fractions of an inch) gather data about current site conditions. The information collected is used to generate a point cloud – a collection of three-dimensional points that represent the surface of an object or space – that can be used during MEP coordination. While minimizing operational interruptions during data collection, this process allows us to efficiently plan and coordinate new MEP systems around existing conditions and reduce installation time. Laser scans also provide a high level of precision for prefabrication and MEP tie-ins.

This was critical during a renovation at Swedish Covenant Hospital, which required tie-ins to the existing structure. Laser scanning allowed early and accurate data collection of the existing structural, architectural and mechanical conditions. Using the point cloud during MEP coordination and prior to fabrication and installation allowed us to identify conflicts between the new systems and existing conditions early in the process. As a result, we’re able to make adjustments to save both time and money.

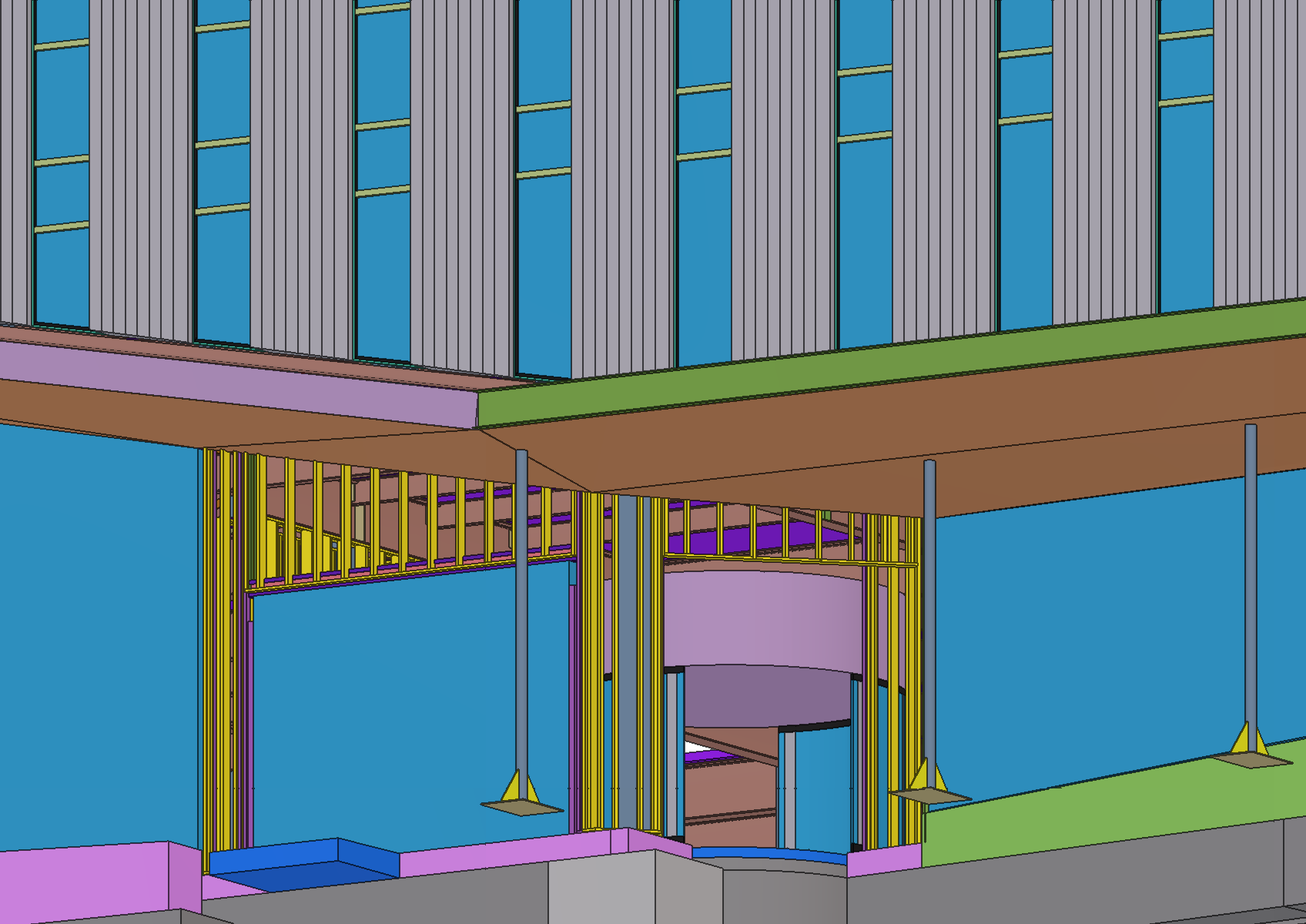

03. Coordinate complex details

At UI Health’s Specialty Care Building, 3D modeling of the different enclosure systems helped coordinate critical details. The model was used with our trade partners to help frame oversized sliding and revolving doors, as well as the associated cantilevered entry canopies. Complex conditions, where precast, glass curtain wall, concrete and fascia paneling came together at patient windows, were fully reviewed in the model to accommodate tight tolerances and expedite installation. The same procedure helped coordinate the connection details of the two-story pedestrian bridge that spanned a two-lane street from the new building to an existing building

04. Maintain agility

While construction models can be used from quantity take off through installation, one of the greatest benefits they provide is agility at all stages. When design requirements, equipment specifications or knowledge about existing conditions change, the model sets up efficient analysis, review and communication of alternate solutions.

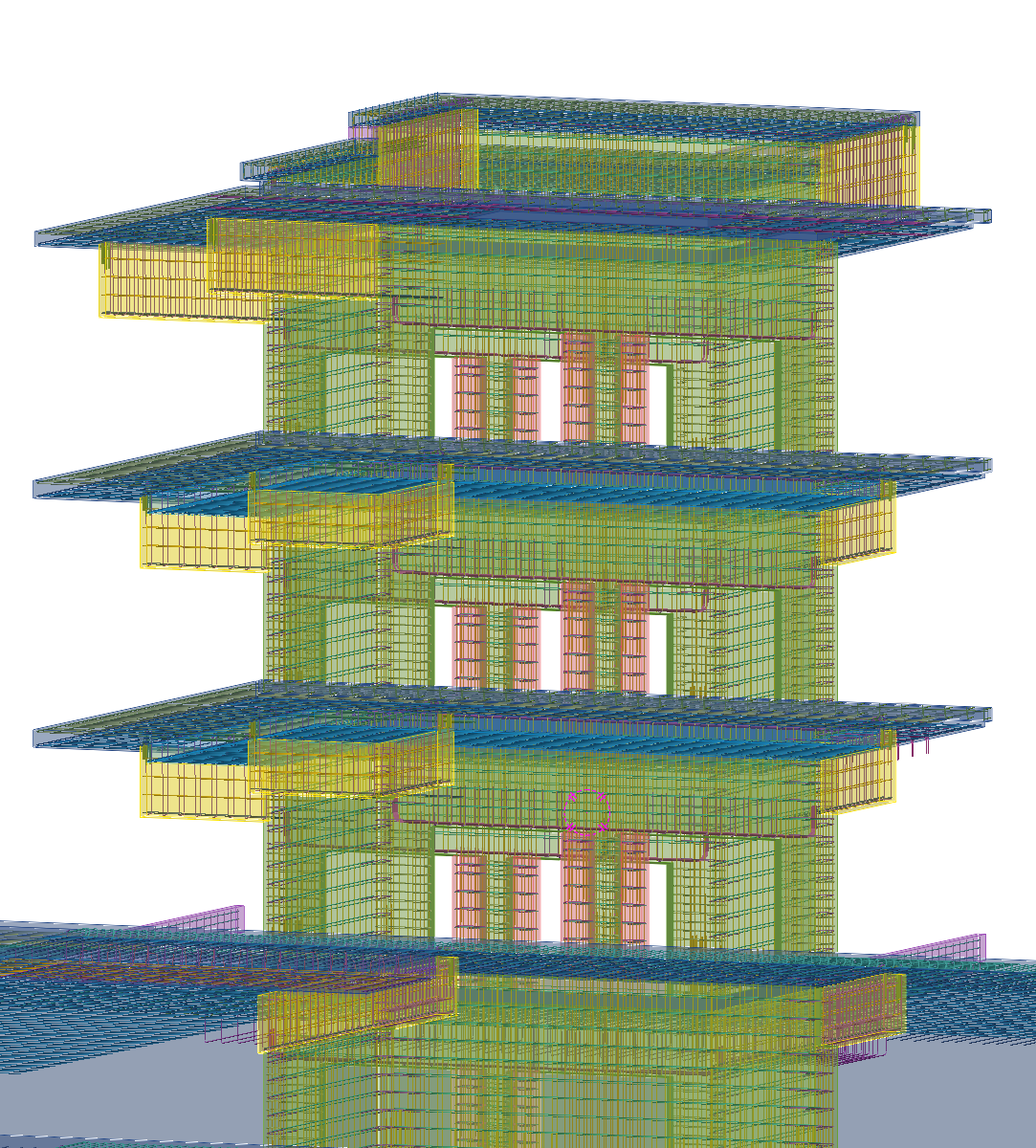

Work at Glenbrook Hospital entailed elevators sized to hold an entire operating team while they moved a patient between intake and surgical floors. These significant elevator cabs required temporary access openings much larger than the final opening sizes. Securing the elevators required a long lead time, and the building had to be weathertight with the roof of the elevator shaft enclosed before the cabs were delivered. The field team identified this sequencing concern through the virtual model. Our team was then able to work through adjustments to the current design and detailed conditions, presenting options to the design team for feedback. The resulting expedited deliverables provided both a temporary and final condition within the schedule constraints.

Below, the Glenbrook Hospital concrete and rebar model shows both the temporary wall condition in green and the orange infills added after the elevator cabs were installed.

05. Expedite the schedule

BIM makes project planning come alive by combining the 2D project schedule with the 3D model to visually depict how the project will be constructed. This helps us proactively address challenges, build stronger partnerships and accomplish the following:

- confirm the baseline schedule

- optimize the flow of work

- plan safety systems and processes

- communicate logistics to the owner and other stakeholders

- refine detailed level sequencing and logistics

- collaborate with trade partners

When Pepper joined the Integrated Project Delivery (IPD) team for the new Ascension St. Vincent Women and Infants Hospital in Indianapolis, our team developed a specific 90-day action plan to fast-track the project. Implementing Lean Construction principles and leveraging different types of technology, we started utility relocation, site demolition and site preparation work within 60 days, finalized the GMP in five months, began foundation work within six months and turned over the new 278,500-square-foot hospital in 22 months from the time we were brought on board. Leveraging different types of technology opened opportunities to incorporate multiple schedule acceleration strategies, including virtual mock-ups for decision-making, extensive prefabrication and productivity tracking through drone flights. We also used laser scans to generate heat maps of the vertical concrete core surfaces to evaluate the as-built condition for fit-up of future systems, including structural steel when fabrication was still ongoing.

06. Visualize future installations

Similar to virtual reality, augmented reality (AR) allows for a preview of a future state. Wearing AR glasses on-site, the team can see current conditions clearly, while also overlaying a graphical representation of future conditions. This helps them visualize the design intent in place, verify accessibility requirements or confirm proper installations. Whether the goal is to double-check embeds, sleeve locations or MEP risers, AR helps guarantee quality and provides peace of mind while promoting expedited schedules.

At Advocate Christ Medical Center, a cost/benefit analysis determined that a new air-handling unit (AHU) should be located on the roof. This created concerns about its aesthetic. What would this AHU look like to neighbors and the adjacent patient rooms? Images taken with a drone were collected and overlaid with a model of the new unit to scale. The owner was able to see what it would look like from multiple locations surrounding the hospital, which alleviated their concerns. The photo shows the unit (in red, circled for clarity) and the view from an adjacent bed tower patient room.

Tech solutions are changing the ways we plan, build and manage projects. They also provide a wide range of benefits. Taking advantage of unique opportunities to bridge physical and digital environments, we’re raising the bar on essential best practices for healthcare projects and across the modern construction industry.