Self perform, Preconstruction

After the housing market crash and recession of the late 2000s and the shift away from mortgaged housing, the demand for cast-in-place apartment towers drastically increased, resulting in a shortfall of qualified concrete contractors and self-performing general contractors. Pepper Construction had the foresight to add experienced concrete leadership and key field supervisors, in anticipation of this market opportunity. Along with strategic staffing decisions, we implemented the latest 3D BIM technology throughout the concrete preconstruction and construction process, resulting in rapid estimates, thorough plans and efficient construction practices.

During this building process our field staff has grown from averaging 130 per day in 2013 to 430 today. In fact, we went from a share of about two percent of the Chicago concrete market to being one of the top two concrete contractors last year.

Consistency pays off

While the industry is still inconsistently adopting building information modeling (BIM), at Pepper, we are committed to using Tekla Structures on all of our concrete pursuits – and the earlier, the better.

Tekla Structures has streamlined our estimating process, allowing us to complete more estimates, in less time and to a higher level of accuracy. Instead of basing early budgets off of cost per square foot and building type, we use project-specific models. We can produce quantities from Tekla at the same rate as our traditional estimators can take off by hand or use 2D take-offs.

While creating the model for estimating, we flag constructability issues, design discrepancies, and unclear intent to assist the overall project planning. We also set up all of our models for use during construction.

Benefits to the owner

We have found many advantages in using Tekla for estimating, and we wouldn’t operate any other way. But are those benefits transferable to our design partners and owners? We believe they are.

For clients who need to see what it will look like, technology provides a visual tool for communication, which can translate into huge time savings in decision-making.

Building an estimating model to construction level detail allows for a one-model approach to consolidating costs. It also has the benefit of applying various BIM and Virtual Design and Construction (VDC) uses earlier and in more detail, increasing the benefits and opportunities downstream.

It’s well known that the earlier changes are made, the lower the cost of implementing those changes. And finding a conflict in a model is much cheaper than finding it in the field.

Results of an integrated approach

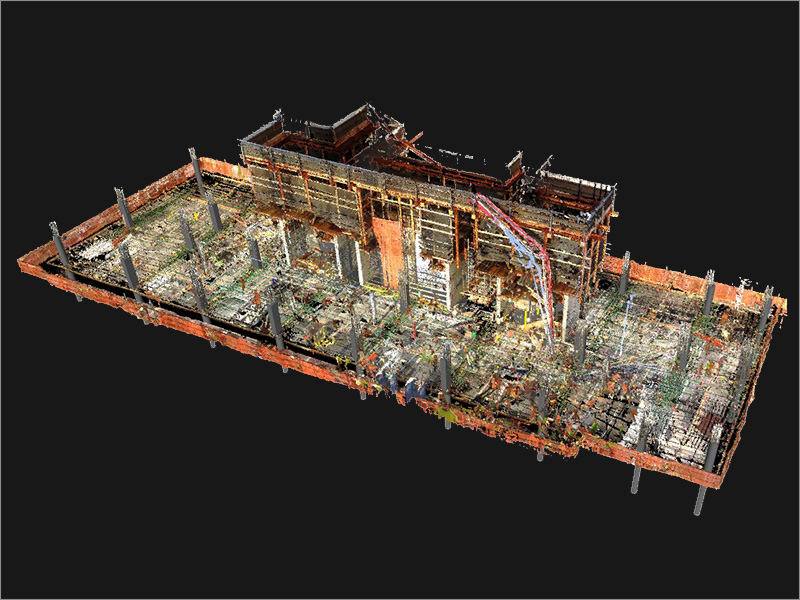

Technology fosters communication as long as it doesn’t live in a vacuum. A 3D model can integrate multiple points of view to develop collaborative solutions. How does our concrete self-perform operation integrate with our other services to provide smarter solutions?

Real-time estimating

Once our model is completed for the self-perform scope, we typically meet with the project team to verify our scope assumptions. We review items like what stair walls were assumed to be concrete verses masonry and where we included concrete curbs and parapets. This allows for a much more comprehensive and accurate price.

As the project progresses, the self-perform and virtual construction team members can provide real-time estimating. The model allows quantities to be calculated instantaneously as changes are made.

One typical concern with estimating models is how to update or compare iterations. When set up properly, the model can be a great real time comparison tool to show changes between iterations.

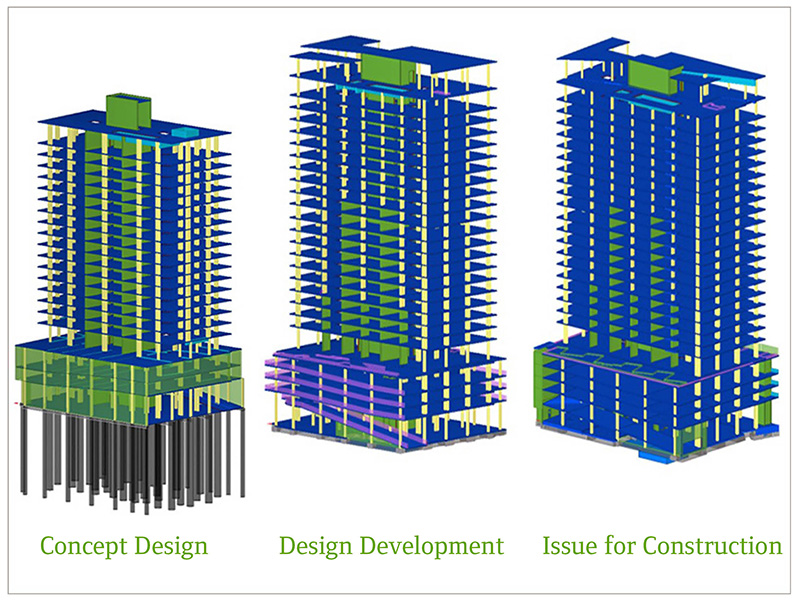

For example, on one high rise project, we were hired as a design-assist partner to help optimize the concrete design, in addition to providing several cost iterations. The image shows three of numerous design iterations. As a result of our preconstruction efforts, we eliminated 300cy out of the walls and 400cy out of the columns. At the same time, we added levels, updated material scope of perimeter walls, flipped ramps, altered slab extent and adjusted column layouts.

The model allows a moment in time to be captured at each cost update and then quantities to be compared throughout the project. The client can see the exact effects of each design change or value engineering effort, and savings can be isolated to the design-assist process, even if the overall quantities and scope may increase.

Advanced estimating - energy modeling

When considering high performance and sustainability of a building, an energy analysis can be conducted during preconstruction. The Tekla models are used as a base in creating massing models for those studies.

Logistics planning

Coordination with suppliers

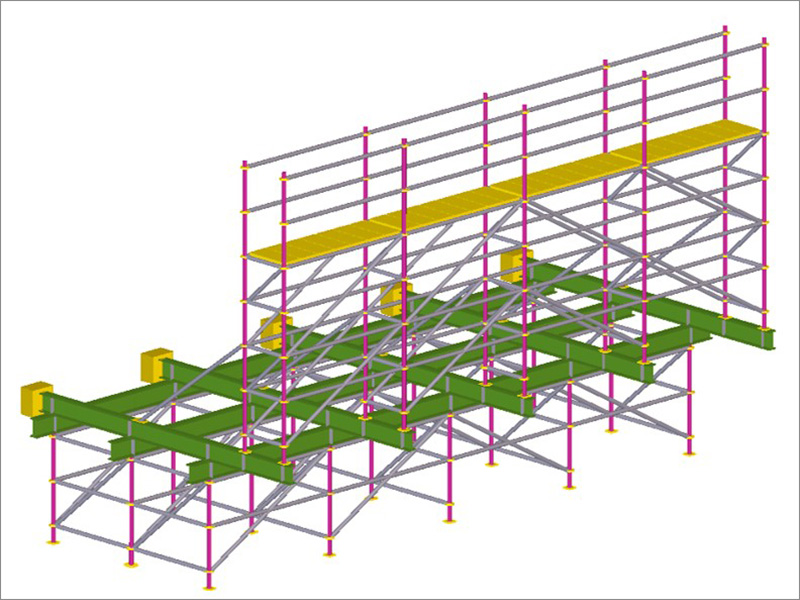

The same estimating model can also be used for coordination with multiple parties. On a retail renovation project, we worked with the scaffold subcontractor to create and model a custom cantilevered system. We overlaid our components in the existing architectural model and helped the client envision what their retail space would look like while improvements were being made.

Quality control

Safety planning

Enhanced performance

As our industry moves toward model-based platforms for designing, estimating and running jobs, there is a struggle with knowledge transfer and ensuring the entire project team can work from one model without duplicating efforts.

Estimating models are a great way to streamline efforts and realize the benefits of BIM early in a project. The key to experiencing all of its advantages is setting up the model in a way that it works for everyone in preconstruction and construction – and then using the data to enhance the project downstream.

About the Authors