Paving a Fresh Trajectory to Zero

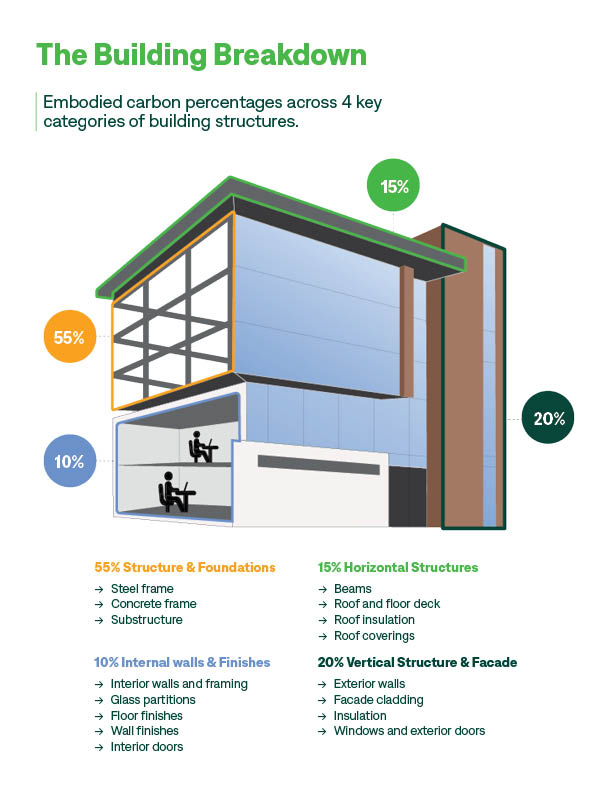

Sometimes, what we can’t see makes the biggest difference. Millions of tons of carbon, unseen and embedded in materials and processes, are released during the life cycle of building products. Buildings are responsible for approximately 39% of global carbon emissions, stemming from both the energy they consume and the materials used to construct them. Cement alone contributes to an estimated 8% of global CO₂ emissions. Industry professionals agree: addressing this embodied carbon is a critical step on the path to net zero carbon emissions. It’s a path that stretches beyond operational efficiency and is linked across material extraction, manufacturing, transport, construction and demolition.

In the vanguard of High Performance and Sustainability, Pepper set about expanding knowledge to equip the industry to make better decisions in what is fast becoming a powerful new horizon for creating meaningful impact.

Beating the Roadblock

With the spotlight on operational carbon for many years now, buildings have become more energy efficient. Energy is also increasingly being generated from cleaner sources. Surging corporate climate pledges, recent SEC rulings and new LEEDv5 standards are turning the focus to this less explored avenue for action.

Client requests for embodied carbon footprint calculations and comparisons are also growing as buildings with low-embodied carbon become increasingly valuable in green building standards and certifications. The roadblock to effectively providing accurate answers: lack of documented proven results that show what can be achieved with different types of buildings, systems and materials.

Undeterred, Pepper created our own Embodied Carbon Database (ECD) to generate empirical baselines for accelerating decarbonization.

If we’re going to reduce embodied carbon, we need to understand where the emissions come from in our built environments,” says Susan Heinking, FAIA, LEED Fellow, Senior Vice President of High Performance and Sustainable Construction, Pepper Construction Group. “The goal is to have reliable information readily available as a solid foundation for decision making, clarity and transparency.

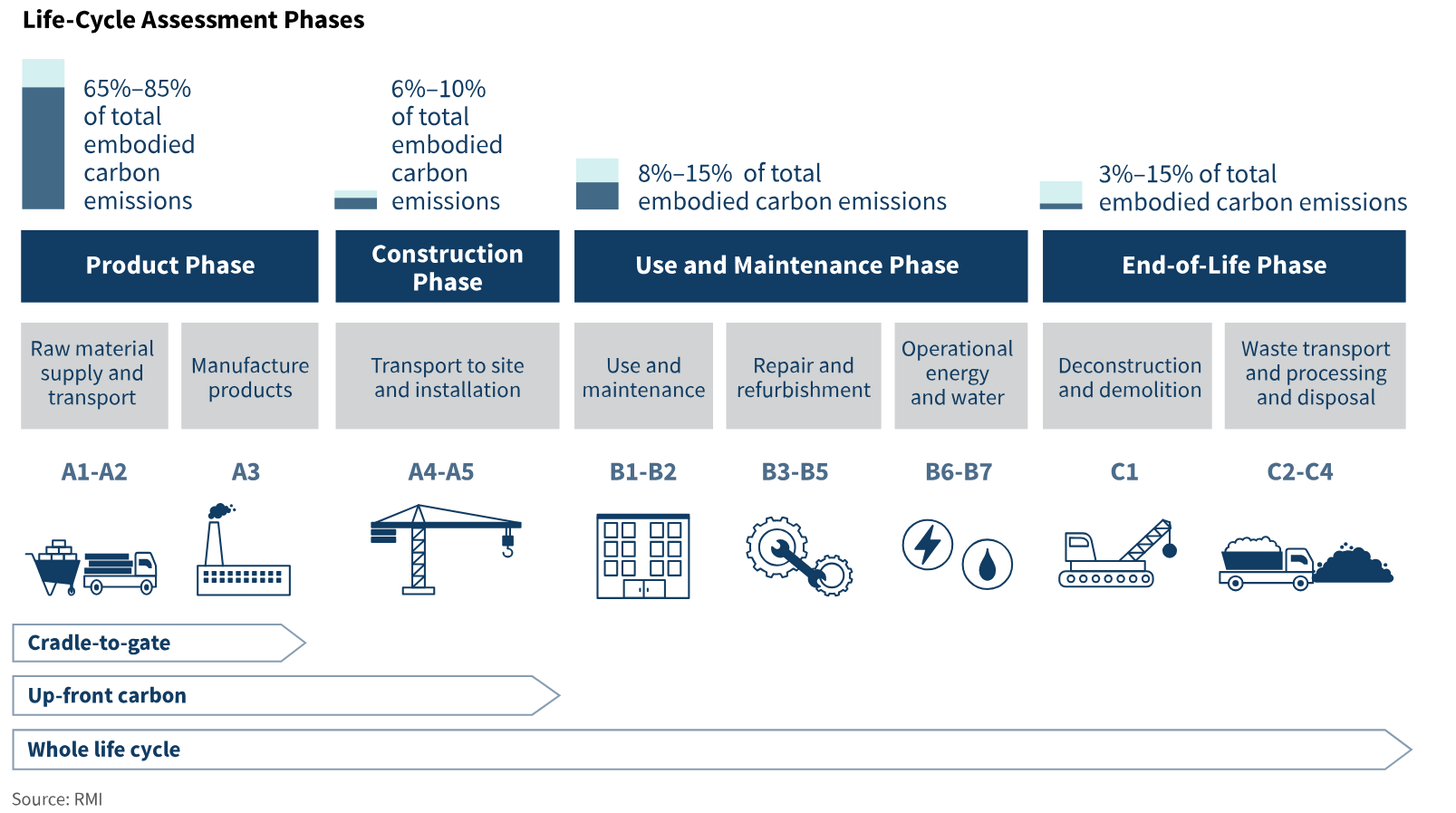

Embodied carbon, the greenhouse gas emissions produced over a product’s complete life cycle, is calculated using metrics that measure the potential environmental impact. This Global Warming Potential (GWP) is expressed in carbon dioxide equivalent units, or CO2e, otherwise known as the carbon footprint. Additionally, the Structural Engineering Institute of the American Society of Civil Engineers indicates that the carbon emissions released before a building is in use, or upfront carbons, are projected to be responsible for half of the entire carbon footprint of new construction between now and 2050.

The ECD began with a sound foundation in Pepper’s extensive expertise across markets and regions, which provided reliable project data. The data was extracted from all projects with available Revit models out of each Pepper office within the last decade. To quantify the embodied carbon and determine the environmental impact, the team systematically completed a life cycle assessment (LCA) for each model.

Supported by Pepper’s innovative culture dedicated to fostering the next generation of talent, the robust investigation engaged interns in getting results.

“We applied 3D Revit models we already had in new ways with One Click LCA software,” explains Natalia Alvarez, Project Manager of High Performance Construction, Pepper Construction. “We divided projects by state, separated new construction from interior renovations, identified project type and site, selected individual building elements from steel beams to concrete foundation to exterior envelope components, and generated data that tells us the amount of carbon associated with each product across the entire life cycle.”

The meticulous effort required detailed vetting by verifying that products were tagged accurately and the disclosures of life cycle impact were aligned with appropriate Environmental Product Declarations (EPDs). The team was also careful to prune the data. The result: a refined, diverse dataset capturing a range of vertical markets, locations, sizes, structural systems, envelope types and finishes.

“Our ECD allows us to quickly identify trends and determine the impact of different systems and materials on a building’s overall embodied carbon footprint,” says Allison Biernacki, High Performance Project Engineer II, Pepper Construction. “Being able to anticipate the footprint based on these proven insights means we can evaluate options for materials and processes to capture carbon savings for clients.”

Considerations are complex—some materials absorb carbon at different life cycle stages; emissions are affected by factors including type and volume of structure, modes and distances of transport, and removal processes; decarbonization opportunities differ between project types and regions. Distilling the expanse of information into tangible figures opens opportunity for conversations with design teams to ensure meaningful carbon reduction strategies can be considered early in a project timeline. The ECD is a critical tool for pinpointing high-impact materials, exploring alternatives and aligning design decisions to avoid costly changes further down the road.

“By integrating these LCAs and EPDs into decision making, we can actively optimize building design and construction to turn our sustainability ambitions into measurable and financially viable impact,” says Susan.

Championing Bold Change

Pepper started the ECD focusing on our designs in 2024, because no database capturing in-depth reporting on embodied carbon existed at the time in the United States. Published data is starting to catch on. A report from the Carbon Leadership Forum reviewing actual building projects in North America that were voluntarily submitted was released in April 2025. Published by the University of Washington’s Life Cycle Laboratory, the report establishes benchmarks in whole-building life-cycle assessment.

Major cities are answering the call. Chicago’s Sustainable Development Policy promotes decarbonization strategies like LEED’s Clean Construction Pilot Credit, which calls for implementing a plan to reduce particulate matter emissions from diesel-fueled vehicles, power generators and construction equipment on project sites. Piloting this credit on the University of Illinois Urbana-Champaign Campus Instructional Facility, Pepper enforced a no-idling policy and prioritized electric equipment that contributed to achieving LEED Platinum certification.

Research, like that being done in the School of Architecture at the University of Notre Dame, is also driving the creation of new visual tools that analyze embodied carbon in buildings to help policymakers plan strategic carbon mitigation.

“It’s one thing to have the idea,” says Susan. “Pepper shines in the follow-through with an entrepreneurial spirit that enables our people to develop and operationalize concepts. We’re boosting critical momentum in the race towards decarbonization by providing actionable insights with the ECD that clients can confidently use to make informed decisions.”

Pepper’s ECD is another way that we’re acting on our commitment to build cleaner, smarter and healthier, and it’s evolving as we continue collecting results from our project base. The larger dataset can empower the industry with a clearer roadmap for setting key benchmarks to track progress, measure effectiveness and drive change essential for building a sustainable future.

“This kind of forward-thinking action supported by expert-driven work,” says Susan, “sets us up for stronger collaborations with industry partners that can change the trajectory to net zero carbon.”