Confidential Manufacturing & Distribution FacilitySafety

Spend five minutes with Keith Goliah and you will feel comfortable, you will laugh, you will know your opinions matter to him, and, most importantly, you will feel safe. These characteristics not only make Keith a good person, but they make him great at what he does. As safety engineer for Pepper, Keith is responsible for ensuring that each person on the jobsite makes it home safely every day. And it’s a responsibility that he has taken very personally, from day one of his career in construction safety.

How he got his start

Keith has been in the construction industry for 18 years, and particularly focused on safety for the last 17 years. Starting as a laborer for a concrete contractor, he had worked his way up to foreman when he was approached with the opportunity to take on a new position. The opportunity was a full-time safety position, a first for the company at the time, and it served as Keith’s first step into the world of safety.

It was during his very first year in his new position that Keith formed his personal philosophy on safety. And it's one that he maintains to this day. He learned the importance of open dialogue. Maintaining an open dialogue with the tradespeople in the field enabled him to build relationships, establish trust and generate buy-in for the new safety program he was creating. He valued their input and feedback, using it to keep everyone on board and accountable when it came to jobsite safety. Quite simply, Keith cared about the people in the field. He understood the importance of having their perspective and support to implement a truly effective safety program. And he made sure that they knew it.

Where he is today

Fast forward 17 years, and the lessons Keith learned early in his safety career are invaluable in his current role at Pepper. Keith is serving as safety engineer on a manufacturing project that covers more than one million square feet. And while a project of this size comes with its own unique set of challenges, Keith hasn’t strayed from his personal approach to safety.

Staying committed

Keith remains committed to his personal approach on jobsite safety so has had to get innovative on how he brings it to a project of this magnitude. From training, to site walks, to basic communication, Keith remains approachable, visible and connected with those in the field.

First impressions

Field onboarding and training for this project was a bit different than other Pepper projects. First, Keith had to merge Pepper's safety procedures with the clients' safety procedures to create a cohesive safety program. It was a collaborative process with the owner and with each company pushing each other to raise the standards of safety on the project.

Second, although almost 75 percent of the contractors have worked with Pepper before and are familiar with our safety processes, the other 25 percent have no prior experience working on a Pepper jobsite. Keith has managed jobsite safety based on two different experience levels, in addition to training everyone on the new procedures and standards that align with the client’s safety program.

Third, the sheer volume of tradespeople on the project requires an extensive training process.

To overcome these challenges, Keith made the training a collaborative, interactive experience. He presents real-life scenarios and engages tradespeople to share their own thoughts and experiences. Instead of just telling them the processes, he asks for their opinions and seeks their understanding of the “whys” of the safety program.

Keith’s goal for this project is to assemble a unified team that collectively looks out for each other. He seizes on the opportunity that the training provides to set the tone for the project, establish an open dialogue and empower each individual to make a difference when it comes to onsite safety.

Not your typical audit

The way Keith communicates and connects with those around him makes people feel comfortable to ask questions and take a hands-on approach to solving problems. Nowhere is Keith’s relationship-building approach more evident than during a safety audit.

Contrary to traditional thinking, Keith’s number one goal when performing a safety audit is to not pull out his phone and take notes. His number one goal is to interact with the tradespeople. He asks them questions and encourages them to ask him questions. If an individual comes to him with an issue, he helps lead them to their own conclusions to identify the best available solution.

Instead of simply telling people the right answer, Keith turns each conversation into a learning opportunity that informs and empowers.

Integrating with the existing workforce

On this specific project, Keith is tasked with coordinating construction activities on an active manufacturing campus. He has to plan and communicate shutdown periods around client operations, maintain separation of activities from campus employees and enforce security standards for restricted areas.

Key to all of this is the planning and coordination process with the owner. For example, Keith initiates conversations between the project team and owner at least one-to-two weeks prior to any shutdown periods. He helps the team effectively communicate the need for the shutdown and ensures that everyone knows which areas will be affected and when.

He facilitates the conversation between the important parties and makes sure that both sides understand the other’s perspective.

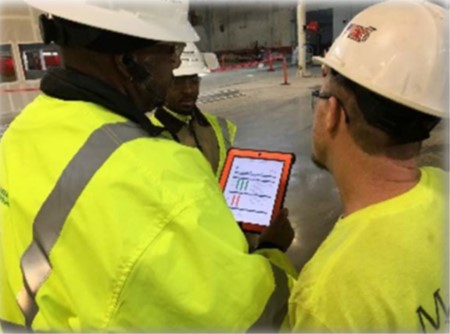

Finally, effectively and efficiently communicating with the team and the owner is a huge challenge on a project of this size. Keith and the project team utilize Zinc, an innovative phone app, that allows communication to happen in a timely manner. The app gives notifications, allows live video messages, sends daily safety reports directly to the foremen in the field and more.

From the director to project foremen, Zinc helps keep the entire project team aware of upcoming activities, like closed-off areas; recognizes individual tradespeople for excellence on the jobsite; informs of any immediate issues, such as weather alerts and shares lessons learned related to jobsite safety.

For example, if Keith is informed about an issue that multiple people have experienced during a site safety walk, he can record a video message and quickly send it through the Zinc distribution list. It’s just one more way that Keith makes himself available to the workers in the field.

Do you have five minutes?

Keith truly embodies Pepper's philosophy when it comes to jobsite safety. He understands his role as connection maker, conversation starter and educator. Keith's passion for safety shows in his everyday work and through the personal relationships he's built throughout his career. Spend five minutes with him, and you will see why.

About the Author