High performance & sustainability, Safety, Environmental

Construction work ranks among the most dangerous jobs in America. As such, preventative safety plans and OSHA requirements are critical to our success. However, traditional safety measures are focused on daily task hazards and high-risk activities, while other subtle dangers lurk on every jobsite, often going undetected until the effects show up 20-30 years later.

Last week, we had the privilege of speaking at the Living Future Unconference in Seattle. Living Future is a source of inspiration when it comes to creating a lasting impact through the built environment.

Our session was titled, "Construction Jobsites are Workplaces Too: Considering the Health of Those Who Occupy Buildings Before Turnover," and in it, we addressed a topic that is starting to come up more and more across our industry - air quality. For us, this wasn't just a presentation; it was a call to action. Over the past year, we've put a lot of energy into improving the environmental conditions in which we ask our teams to work. After all, just because it's a construction site, it shouldn't mean our employees and trade partners should lower their expectations about working conditions. Our Net Zero trailer is one of our strategies, but it only addresses the project office. To make a bigger difference in our industry, we have to consider the health of our most prominent workplaces - our construction sites - which still have room to improve.

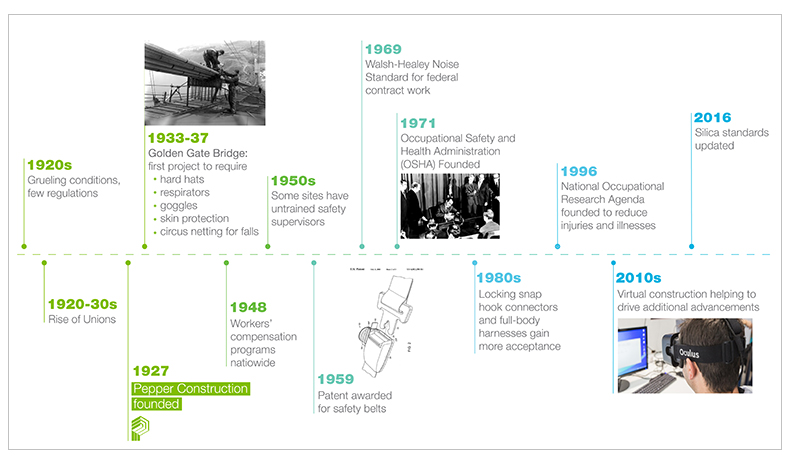

Learning from the past

In the first part of our talk, we set the stage with an overview of historical safety measures, as depicted in the timeline below. We've come a long way!

We also shared the environmental hazards we deal with today because of past decisions and unknowns. Pepper Environmental Technologies is charged with addressing the worst conditions on our jobsites. From our experience, we shared the realities of some of the most dangerous materials, where they're found, how frequently we come across them and how they are addressed. We have situations in which we have to remove hazardous products that could affect end users. However, to do so, somebody has to physically remove it. Workers can be exposed to inhalation, ingestion and dermal exposures during removal.

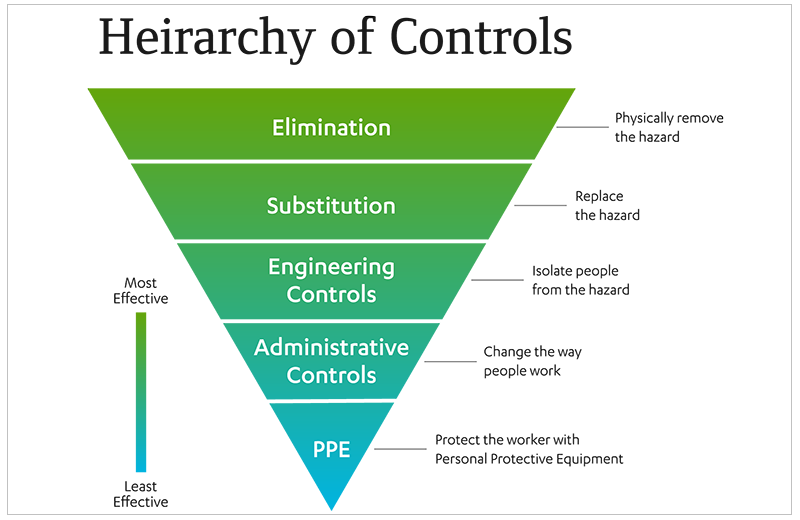

Engaging the design community in safety planning

The diagram below is the model our safety team follows when developing safety plans, where the most effective activities eliminate the hazards rather than simply protecting workers from the hazards. Our industry has been very good about implementing policies designed to keep our workforce safe. Typically, our safety measures can effectively address the first three or four steps. However, through various measures we've taken at Pepper, we've come to realize that when it comes to air quality, no amount of protection will completely erase all exposure to every hazard. It's just not enough with particulates small enough to penetrate the skin.

So instead, our next step is to create awareness in our industry, and particularly among the design community, about what hazards can't be eliminated through our current safety plans. We want to form closer partnerships with the design community and trades in support of the National Institute for Occupational Safety and Health's (NIOSH) Prevention through Design (PtD) initiative, which was specifically created to: "prevent and control occupational injuries, illnesses, and fatalities through the inclusion of prevention considerations in all designs that impact workers."

As such, we see the biggest opportunity for prevention with the materials that are specified by designers. The more our industry references Living Building Challenge Red List-free materials and other healthy materials databases, the better for our workforce. It won't be easy, but it will be well worth the effort.

Living Future was a first step in what we hope is the start of a fruitful conversation about creating a healthier construction workplace. If you are interested in learning more or would like to join the conversation, we encourage you to contact us.

About the Authors