High performance & sustainability, Industrial and manufacturing

The characteristics and benefits of LEDs in manufacturing and industrial facilities - improving quality, safety and productivity

Lighting plays a significant role in the built environment. In commercial construction, it's considered for both its aesthetic and functional value. As such, it is a system that owners choose to upgrade. When owners request a life cycle cost analysis, lighting is one of the first places I look for efficiencies. LEDs offer numerous benefits, as the technology has advanced well beyond that of incandescent and fluorescents.

The past couple of years in particular, increased competition and continued focus to bring costs down have resulted in more competitive pricing and larger supply. Thus, the time it takes to recoup first costs is also diminishing – sometimes to within one or two years.

What is LED technology?

Light–emitting diodes (LEDs) are semiconductor devices that produce visible light when an electrical current passes through them. You will also see them referred to as an SSL - a type of Solid State Lighting – as opposed to a filament or gas.

If you have purchased LED bulbs for your home, you have seen the options. They come in similar shapes and sizes, making a home retrofit as easy as changing out a light bulb. Some of the differences between filament bulbs are also apparent:

- Brightness – Because they are designed to reduce the amount of energy needed, LEDs are measured in lumens, or brightness, instead of wattage. They require fewer watts to achieve the same level of brightness.

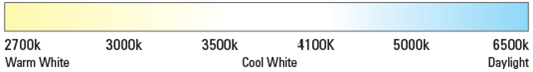

- Color – Unlike filament bulbs, LEDs offer a spectrum of colors, ranging from yellowish warm white (2700k) to bluer daylight (6500k). The Kelvin scale is used to determine the degree of white - warm versus cool.

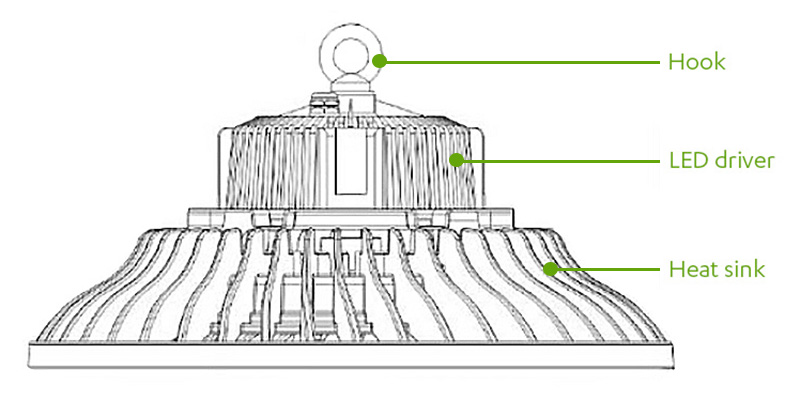

- Weight – LEDs are heavier because they contain their own heat sink, which draws the heat instead of giving off the heat, allowing them to burn cooler.

Manufacturing and industrial spaces are different

While LEDs found their way into commercial buildings, manufacturing and industrial facilities were some of the last to invest in LED lighting - and for good reason. Like commercial buildings, industrial spaces must meet ASHRAE standards and regulatory requirements.

For our build-to-suit projects, lighting is very important. However, in the spec warehouses we build for developers, they usually incorporate the minimal amount of lighting, to prevent spending money upfront that won't get used until they know the tenant requirements. Therein lays the reason for the slower adoption – and the opportunity. Since developers are constructing the buildings, many industrial LED projects today are retrofits because tenants are the ones interested in the lighting.

As technology evolves to make retro-fits almost as easy as changing out a light bulb, we're seeing more tenants and owners making the switch. With lower costs and the availability of incentives and refunds, developers are also starting to consider the upfront investment in LED lighting, to make their buildings more marketable.

Though LEDs offer multiple advantages, until recently the technology has not been developed enough to allow these types of businesses to experience the benefits at a price point that makes sense.

Characteristics and benefits of LED Lighting

With cost as the main drawback – and shrinking - LED lighting offers the following characteristics and benefits that far outweigh traditional lighting:

Efficiency

LEDs operate by making electricity so they consume less energy or wattage than other sources. From our experience, because of the size of LEDs, it typically takes more LED high-bay lights than fluorescent. Energy savings vary based on types of space and usage and can reach 70 percent and sometimes more.

Temperature

It's a misconception that LEDs don’t produce heat. Instead, the heat is contained in the heat sink, and thus, stays within the device and burns cool. Since LEDs give off less heat, they also help reduce the load on other systems, like the AC and refrigeration systems.

Color

There is no such thing as a white LED light. Instead, colors include amber, red, green and blue, which are mixed or covered with a phosphor material that converts the color of the light. Different formulas allow for different degrees of white. The ability to control the lighting color is ideal for color-critical applications such as quality control inspections and showcasing products.

Longevity

With conventional lighting, facilities often over-light to compensate for a loss in lumen output. LEDs lose very little lumen output over the course of a 10-year life span, which means you get brighter, more efficient light over a longer time. The low maintenance allows for continuous manufacturing and eliminates costs associated with fixing and maintaining lights, including fixtures, bulbs, renting equipment and the labor. It eliminates downtime and improves productivity.

Flexibility

LEDs come in multiple shapes and sizes to cover diverse lighting needs. This feature is important for task lighting and assembly areas in manufacturing spaces that vary from the plant and warehouse to inspection areas. Size is a unique feature to LEDs; their compact design can be used in tight-fitting or narrow spaces.

Instant-on

Unlike CFLs, LEDs turn on instantly, with no warm-up time. This allows them to be placed on timers and occupancy sensors to use the lights when needed. Standard fixtures have to be left on longer to avoid warm-up time.

Directional

LEDs focus light in one direction and have to be engineered to distribute light to a broader area. This is an advantage for task lighting where it helps to focus the light where it is needed, like on a production line. For general lighting and outdoor lighting, reflectors are used to distribute the light to a wider area.

Durability

LED fixtures are tough and can withstand harsh conditions. Their ability to resist vibration makes them a great source in rugged, heavy manufacturing environments.

Safety

Unlike CFL bulbs, LED lights contain no mercury or hazardous materials and can be manufactured with metal and plastic instead of glass. This eliminates the cost of disposal, increases its recyclability and reduces risks to humans. Further, the performance meets the GMP and FDA codes for areas like refrigeration and food packaging.

Clean in place

LEDs can be made out of cleanable materials that can withstand chemical and high temperature wash downs, which are common for FDA or food packaging, without the need for additional lighting enclosures, which adds cost. When used on a supplementary DC power circuit, LEDs will withstand temperatures upward of 150° F (70° C), which is good for heat treated facilities.

Smart

The technology around LEDs continues to be developed. Already, advancements exist that allow daylight to be harvested. Sensors can measure and manage available light and adjust each fixture's output to achieve a desired light level. Optics packages can be used to optimize light in racked aisles (narrow optics) and open spaces (wide optics) for an even distribution. Finally, LEDs can be networked and monitored remotely. Facilities managers can see the remaining life span and adjust timers and sensors from their desks.

Glare

One reported performance drawback of LEDs is glare. With the ability to control output and as technology continues to improve, I expect glare will become less of an issue. For now, diffusing lenses and light placement help with this.

So what are the costs and return?

It's hard to compare the life of an LED bulb to an incandescent or fluorescent because LEDs don't "burn out" or fail. Their life is defined by lumen depreciation of 30 percent, which equates to approximately 10 years.

Several sources indicate the up-front cost of an LED upgrade is about twice the cost of conventional fixtures, with a significantly lower total cost of ownership. First costs can be offset by tax incentives, grants and utility rebates, which in some cases brings down the payback period to within a couple of years or even less than a year. Others suggest up to 80 percent savings with a payback period of four years. The cost and return will vary based on the design.

Funding for incentives and rebates varies by state and programs are replenished on an annual basis. Some funds are used up earlier than others. According to Briteswitch, 24 percent of programs ran out of funding in 2015, which doubled the average number of programs that ran out in previous years. For those considering a retro-fit or new installation project, there is a pre-approval process, and incentives vary based on the products selected.

The factors that go into evaluating operations costs include utility costs, maintenance costs (materials, equipment rental and labor) and replacement costs, including disposal. Owners should factor in the total cost of ownership, which includes loss in productivity, eliminating compounded energy usage and safety exposures. Those can be harder to quantify but often are worth more.

Where does it make sense to invest in LED lighting?

All facilities can benefit from LED lighting. Naturally, LED fixtures deliver the fastest return where there are longer periods of time (15 hours or more) when the lights are on. LEDs should also be considered whenever there is an operational advantage.

As we've prepared cost analyses, the area that has presented the fastest return and received the quickest adoption is outdoor lighting. LED lighting is superior to metal halide performance in terms of quality and quantity of light, price, energy efficiency and reliability. When considering LED outdoor lighting, the American Medical Association (AMA) stresses the importance of proper design of new technologies and the close connection between light and human health. For example, the AMA recommends that outdoor lighting should have a color temperature of no greater than 3000 Kelvin (K) at night. We recommend that all LED lighting be properly shielded to minimize glare and be dimmable for off-peak hours.

The second trend we are seeing is retrofitting existing facilities. Technology has evolved to allow for the removal of the ballast and bulbs and installation of a conversion piece in the existing housing. These kits make a conversion more cost-effective than replacing the whole fixture.

Another application to consider is cold storage because of the reduction in thermal load on the cooler and higher sustainable light levels.

Finally, for color-critical applications such as quality control inspections, LED's variety of color temperatures allows for accuracy and a better environment for employees to complete their tasks.

What's next?

Researchers are focusing their efforts on pushing the technology and making LEDs even more affordable. Prices have significantly dropped, and various sources predict that in the next 5-10 years the cost of LED bulbs will rival that of incandescent. Already, the manufacturing of incandescent bulbs has decreased while dollars spent on R&D for LED technology is increasing. Regulations support this trend by eliminating the light sources that consume the highest amount of energy and encouraging incentives and rebates that make a conversion more affordable.

Where is the technology headed? LEDs offer what other light sources can't – control and connectivity. Researchers are exploring ways to improve quality, by looking at new colors – for example, a shift from blue to violet – and adjusting and mimicking lighting in real time. The internet of things and wireless technology will allow facilities to sync several environmental inputs, like lighting, shading and temperature controls, to maximize building efficiency even further.

Finally, research has shown that lighting has a direct impact on productivity and health. According to the National Institute of Health (NIH), "Circadian rhythms are physical, mental and behavioral changes that follow a roughly 24-hour cycle, responding primarily to light and darkness in an organism's environment." Circadian rhythms are driven by our biological clocks and impact how our body functions, and particularly our sleep patterns. Generally, people are sleepiest between 2:00-4:00 am and 1:00-3:00 pm. Since LED lighting is able to mimic natural light and the color change over the course of the day (dawn to dusk) more than any other type of lighting, LEDs can improve employee health and productivity by providing an environment in which it is comfortable for them to work. In facilities where 3rd shift work takes place, LEDs offer a real advantage, and already, case studies have shown that employees enjoy the brighter and more uniform lighting of LED technology.

At Pepper, we help our clients evaluate total cost of ownership. If you have a question about what LED lighting can do for your operations, ask us. We want to help.

About the Author